Are you confused about which 3D printer is best for you?

We break down what a new user should consider when shopping for a new 3D Printer.

Are you interested in buying a quality desktop 3D Printer at an affordable price, but not sure where to start?

This guide was created to help beginners answer the question, “Which 3D Printer is right for me?” There are many options out there, so we explain some of the most important features to consider.

The Ultimate 3D Printer Goal?

At the end of the day, we all want a printer that performs well, and lets us bring our ideas to life.

We do not want to “fight” with a printer that doesn’t perform well, and leaves us feeling frustrated.

By understanding the different hardware and software options on the market (and how they affect your printer’s performance), you will be able to compare them for yourself and decide which 3D Printer is best for what you want to create.

Things to Consider

User Interface

The user interface is what you will be looking at every time you use your 3D printer. It allows you to start prints, and control all your printer settings.

On many affordable 3D printers the User Interface is an afterthought, or simply an open source option.

Since the user interface is a place that you will spend a lot of time, it’s important to ask yourself a question when considering a 3D Printer… Is the User Interface pleasant to use?

The Mantis 3D Printer has a proprietary user interface that is simple, clean and easy to use! It has everything you need to start a 3D Print, and enjoy the process while doing so.

For expert users, all of the advanced functionality and control is easily available “under the hood”… but for most users our “Just Press Print” user interface is all they ever need to worry about!

Build Volume

Build volume refers to the maximum size your 3D Printer is capable of fabricating.

Typically, you want a printer that provides maximum build volume without taking up too much space, or driving price way up!

While 6” x 6” x 6” is adequate for most hobbyist 3D printing, having a larger build volume provides more freedom to create.

The Mantis 3D Printer has an 8” x 8” x 8” build volume, one of the biggest in its class! This additional build volume affords much greater design freedom, without breaking the bank.

On-Board Camera

Premium desktop 3D Printers often include an on-board camera.

An on-board camera allows users to take time-lapse videos of their prints, as well as check on a print-in-progress from another room!

Both of these features are very useful to have.

The Mantis 3D Printer has an on-board camera, just like its much more expensive competitors. This is one of the reasons the Mantis 3D Printer is such a compelling value.

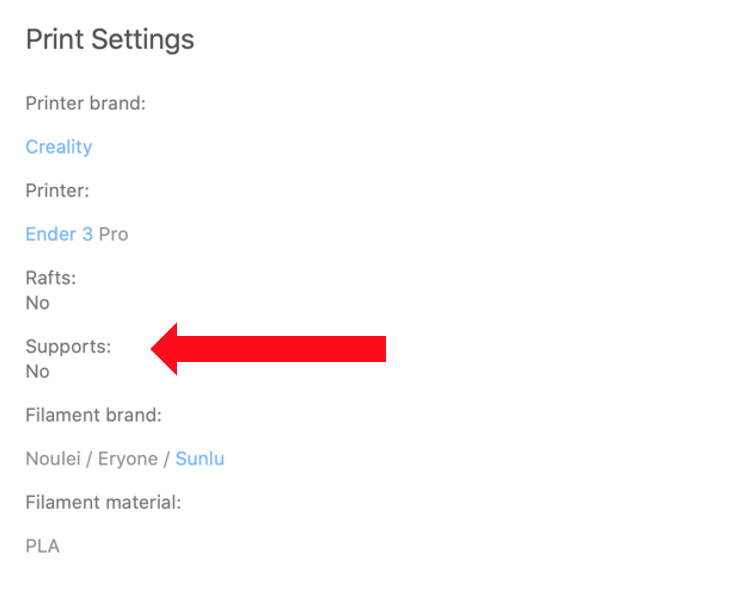

Fully Assembled vs Kit

Do you want to assemble a kit from scratch, and build your own 3D Printer? Do you want to fine-tune a 3D Printer after it’s assembled?

For some, the thought of building and fine-tuning a 3D Printer sounds exciting!

For many other users, they prefer to simply buy a product that works right out of the box.

Each Mantis 3D Printer is fully assembled, and fine-tuned by our talented staff before it leaves our factory. This saves time, frustration, and leaves you ready to enjoy your 3D Printer from the moment you open the box!

Self-Leveling

In order for your 3D Printer to perform its best, the print bed must be properly leveled before use.

Many desktop 3D Printers require you to manually adjust and level your print bed using wrenches or thumb screws.

While this method works, it is time consuming and requires the user learn a great deal about how their printer’s adjustments work.

The Mantis 3D Printer completely automates the bed-leveling process. It has an intelligent probe that senses the precise position of the bed, and maps any discrepancies in bed level. The onboard computer is then able to compensate for these discrepancies to ensure a high-quality print every time.

This time-saving feature makes a massive difference in real-world performance, and makes the Mantis 3D Printer a joy to use!

Removable Magnetic Build Plate

Many printers require you to prep the print surface with blue painters tape, disposable sheets, hair spray, or some other method of promoting adhesion.

Once a print is complete, finished 3D Prints must then be pried off using spatulas and/or fingertips.

This process has been a frustrating pain point for years.

The Mantis 3D Printer has a removable magnetic build plate that makes life easy! The build plate has a special textured surface to ensure excellent adhesion without the need for any aftermarket solutions.

The Mantis 3D Printer makes removing 3D Prints a breeze as well. Simply pick up the removable magnetic build plate, and flex the sheet in your hands.

This gentle flexing of the spring steel sheet will “pop” your parts right off!

To reset, simply return your build plate to its original position, and the magnet will secure it in place. You are ready to start your next print.

Software Pre-Installed

Most 3D Printers require you to download several different software programs before you can start printing.

Functions like .STL File Repair, Slicing, and Controlling Printer Settings each required you to download and learn to use a unique piece of software.

The Mantis 3D Printer has resolved this headache by pre-installing all the required software on the onboard Rasberry Pi micro-computer!

Having all the software pre-installed saves time and frustration, and allows you to start using your 3D Printer right away.

Not only is all the required software pre-installed, but it’s fully automated to make life even easier.

Fully Automated

Historically, desktop 3D Printers required you to go through 10 separate steps before you can 3D Print your part.

It was up to a user to understand the various steps involved, making the learning curve for new users very steep.

The Mantis 3D Printer makes 3D Printing easy by automating all of these complex steps.

On the Mantis, a new user has to 2 simple steps to learn.

Select your file

Press “print”

From there, the Mantis handles everything else.

Your file is automatically repaired, oriented and sliced. The G-code is fed to the printer as everything comes up to temperature.

All of the temperature and extruder feed settings are optimized at the factory to ensure great performance.

The printer will even perform a 9 point bed check to ensure the bed is correctly leveled, and automatically compensate if necessary!

All of this action happens flawlessly and automatically in the background, as a new user watches their part come to life without having to worry about the underlying process.

The Bottom Line

There are many great options out there if you’re in the market for a quality desktop 3D Printer. By understanding how technical features affect real-world performance, you are better able to decide which 3D Printer is best for you.

If you have more questions about the Mantis 3D Printer, we invite you to watch this video from our Founder, Joe Sinclair.